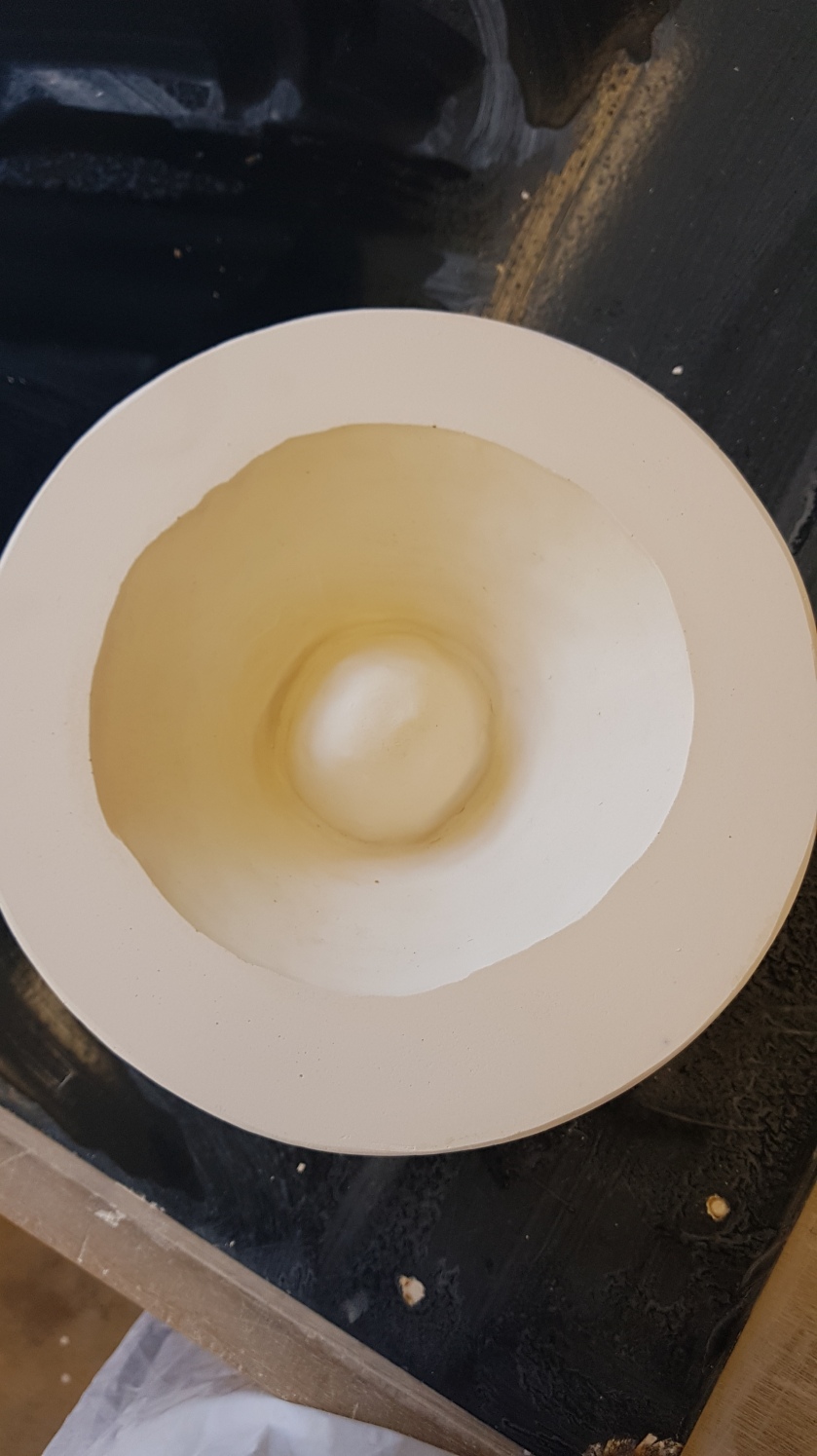

Having made and bisque fired the mortar and started sketching its surface texture I now feel I need to respond to the sketch by making. I have decided to make some useful functional items for ink making in response to my sketches, I have experimented with form on these two pieces but applied a similar texture to the mortar. The purpose of these objects in this project is to respond and develop a texture from a physical space to a 2D space and back again etc. I feel this conversation elevates the stone like quality and the material itself into a different space, demonstrating the capabilities of the clay as well as the tool used, a cutlery knife. By elevating and bringing attention to the texture I feel I have changed the whole purpose to the project. I have decided to not make a final pestle to accompany the mortar as it would detract from the experience of the mortar. Making the mortar was the aim for the first part of this project, fulfilling the bowl requirement of the project, however, the bowl outcome has really changed my orientation for this half of the project. The importance of the bowl, the mortar, being a singular outcome and my pursuit to present a sketch or series of sketches as the second outcome is fundamental as my response to the brief.

The mortar is a functional item which is missing its sibling component. The lack of a pestle is my intention of highlighting the physical attributes of the mortar. Although I initially wanted to make a psetle to accompany the mortar therefore making a fully functional set to use in ink making, I realised with further exploration of the mortar and also after making test pestles that my response to the brief had changed. I knew I needed to reflect further when I was doubting making a pestle. Re-visiting the brief I realised that my Gesamtkunstwerk, my ideal project and outcome would be to make, sketch and fulfill an idea but in actuality my ideal would be the freedom to be reflective in a project and to realise and actualise new intentions. I found beauty in the surface texture and I realised that I wanted to respond to that, I felt that this was now the avenue to follow. My new words for this project are; reflect, realise, respond and actualise.

Although I have not been conventional during this project with sudden understandings of my actual intentions I feel I have developed the project in live time and in a way, listened to the things that I made. I do not feel that I have abandoned aspects of my ideas but realised and made connections with possibly what my consciousness was telling me. I intend to complete the pestle and mortar set but not as part of this project. The mortar’s function will be used, as to its original purpose, next term.